A brewery might seem like an unusual place to test cutting-edge remote industrial monitoring and automation — but for Curtin University student Jake White, it was the perfect proving ground.

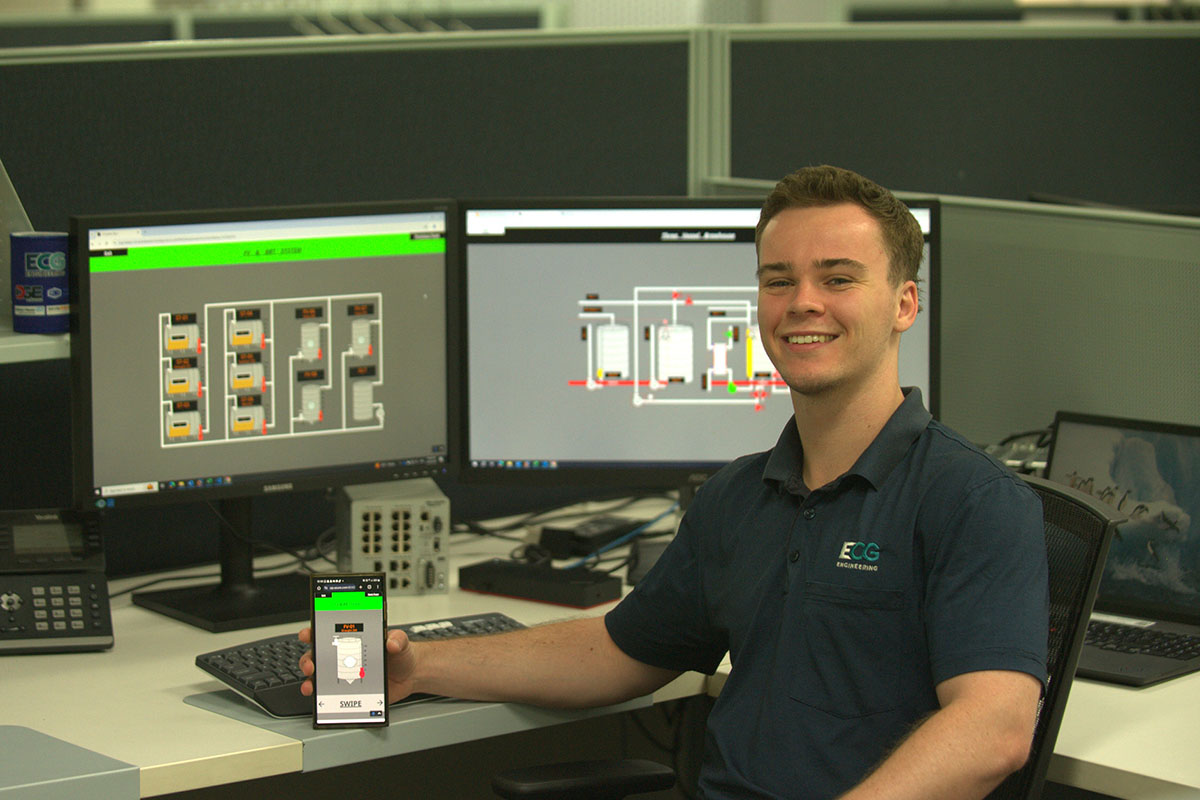

Jake joined ECG through the university’s Industry Exchange program, applying his engineering expertise to an exciting hands-on project.

His challenge? Designing a remote-access SCADA system that brings real-time monitoring and process control to the cloud. To put his work to the test, he implemented the system at Bailey Brewing Co., integrating Siemens PLCs with Ignition by Inductive Automation to create a browser-accessible platform for real-time brewery operations.

The goal was to create a secure, scalable solution that allowed operators to monitor equipment performance, process parameters and alarms remotely via a web interface. The system provides real-time access to data such as:

– Temperature and pressure readings in fermentation and storage tanks.

– Flow rates and pump status during brewing and transfer processes.

– Ingredient tracking for consistency in production.

– Energy consumption data to support efficiency improvements.

By integrating Microsoft Azure’s cloud infrastructure, Jake implemented a fully remote-accessible SCADA system, eliminating the need for on-site servers while maintaining secure data transmission through SSL/TLS encryption.

Jake took the project from a research concept to a fully operational industrial application. He played a key role in data acquisition, cloud connectivity, security implementation and user interface design, gaining valuable hands-on experience in industrial automation.

Andy Griffin, Executive General Manager of ECG Engineering, said:

We are proud to partner with Curtin University and support emerging talent like Jake. His work has been outstanding and we’ve been really impressed with how he applied his skills to solve real-world problems.

Jake’s contribution to this project has directly benefitted our business and we look forward to continuing with these academic partnerships in the future.

EXPANDING THE APPLICATION OF CLOUD-BASED REMOTE ACCESS AND MONITORING

While this project was developed for a brewery, the technology and approach have significant potential for the mining and resources sector, particularly for ECG Engineering’s clients in mineral processing and plant operations.

Mine sites often have complex, geographically dispersed operations that require continuous monitoring. A cloud-based SCADA system provides:

– Remote access to processing plant data, reducing the need for engineers to be on-site.

– Integration with predictive maintenance systems to detect potential equipment failures early.

– Improved scalability, allowing additional sites and systems to be integrated into a centralised platform.

– Stronger cybersecurity measures protecting operational data from unauthorised access.

ECG Engineering is proud to support emerging engineers in applying their skills to addressing industry problems. This project is an example of how the mining industry and academia can collaborate to bridge the gap between theory and practice, fostering innovation and driving progress. Speaking of his experience, intern Jake White commented:

My Industry Exchange internship with ECG has recently ended, and I have nothing but positive things to say about the experience. Completing my first engineering project has boosted my confidence and given me valuable insight into the industry.

Industry Exchange was amazing at setting up my work placement and was an always available asset to reach out to during the internship. I couldn’t recommend Industry Exchange more for students seeking paid internships.